Fluidmax stands for quality — it’s at the core of every rotary gear pump we create.

A Leading manufacturer of high-quality rotary gear pumps

Your Trusted Partner in Fluid Solutions

Fluidmax, a division of Harivallabh Roto Industries, began its journey in 1999.What began as a small-scale operation has now grown into one of India's largest and most respected manufacturers of rotary gear pumps.

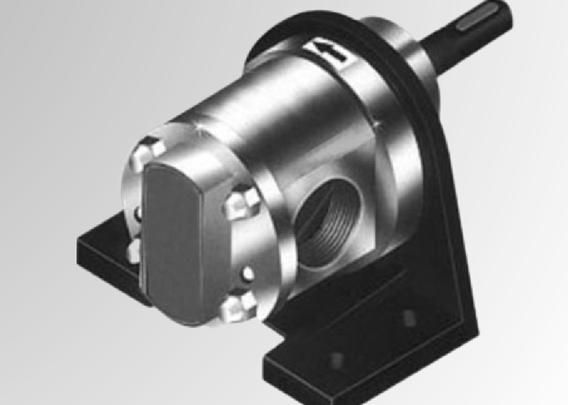

With a wide range of rotary gear pumps offered under the Fluidmax brand, we address the diverse needs of industries requiring reliable fluid transfer solutions. Our pumps are known for their precision, durability, and exceptional performance, which has helped Fluidmax gain significant trust.

Our strength lies in our dedicated team of engineers, skilled professionals, and a commitment to delivering consistent quality. Our proactive approach and customer-centric philosophy ensure that we provide innovative solutions tailored to our clients’ specific needs.

At Fluidmax, we believe that our customers' satisfaction is the foundation of our success. We continually strive to offer cutting-edge products that meet their exact requirements, ensuring long-term reliability and performance.

"Fluidmax – Powering Progress with Precision, Driven by Quality."

Engineered for Longevity

Our rotary gear pumps are built to last, even in the harshest operating environments. With robust materials and proven design, they deliver reliable performance and extended service life, reducing maintenance and downtime.

High-Pressure Performance

Engineered for strength, our pumps are capable of handling high-pressure operations with ease. Their robust design ensures consistent fluid transfer, even in the most demanding systems.

Precision Sealing, Maximum Efficiency

Tight internal clearances reduce fluid loss and improve overall efficiency. Each pump is built for accurate, leak-resistant performance, ensuring smooth and consistent operation.

Our Goal And Vision

Our goal is to be a trusted leader in fluid handling solutions by delivering innovative, reliable, and efficient rotary gear pumps that meet global standards. We envision a future where advanced engineering, customer focus, and continuous improvement drive sustainable growth—for our company, our clients, and the industries we serve. Through a commitment to excellence and forward-thinking, we aim to turn today’s challenges into tomorrow’s opportunities.

Leadership is the capacity to translate Vision into reality.

Our Products

See What Clients Are Saying

We are very proud of the service we provide and stand by every product we carry.

Read our testimonials from our happy customers.

Harivallabh Roto Industries delivers outstanding service! From their top-notch products to their impeccable customer support, every interaction with them has been smooth and efficient. Their dedication to quality is evident in the durability and reliability of their products. I highly recommend them to anyone in need of rotational molding solutions. Truly a company that exceeds expectations!

Harivallabh Roto Industries sets the benchmark for excellence! Their products are not just reliable but also innovative, catering perfectly to diverse needs. The team’s professionalism and promptness in addressing queries reflect their commitment to customer satisfaction.

Harivallabh Roto Industries is a game-changer in the field! Their products are unmatched in quality and durability. I’ve been consistently impressed by their attention to detail and commitment to customer satisfaction. From start to finish, their team ensures a smooth and hassle-free experience. Their expertise in rotational molding is evident in the precision and reliability of their products.

Harivallabh Roto Industries is a name you can trust! Their dedication to quality is evident in every aspect of their service. From the initial inquiry to the final delivery, their team ensures a seamless experience. Their products are not only durable but also innovative, meeting the needs of various industries. What truly sets them apart is their commitment to customer satisfaction; they go above and beyond to exceed expectations.

LOOKING FOR Our Products ?

A leading manufacturer of high-quality rotary gear pumps

Make An Appointment Today ..

INDUSTRY WE SERVE

Our high-quality rotary gear pumps are designed to meet the demanding needs of various industries. Here are some of the key sectors we serve:

Oil and gas

Sugar Plants

Cement Plants

Power Generation

Pharmaceuticals

Marine

Frequently Asked Questions

Choosing a bitumen-jacketed gear pump.

- Temperature Control: Bitumen has a high melting point and needs to be kept at elevated temperatures to maintain a workable viscosity. A jacketed gear pump allows for the circulation of a heating medium (like hot oil, steam, or hot water) through the jacket, keeping the bitumen at the required temperature and preventing solidification.

- Efficient Handling of Viscous Fluids: Gear pumps are positive displacement pumps, making them highly efficient for moving high-viscosity fluids like bitumen. They can handle the thick, sticky nature of bitumen without significant loss of efficiency.

- Constant Flow Rate: Gear pumps provide a constant, non-pulsating flow, which is beneficial for processes that require a steady and controlled transfer of bitumen. This is essential in applications like road construction and roofing, where consistent application is critical.

- Durability and Reliability: Bitumen is abrasive and can be chemically aggressive. Gear pumps designed for bitumen applications are typically made from robust materials that can withstand these harsh conditions, offering long-term durability and reliability.

- Ease of Maintenance: Jacketed gear pumps are often designed with maintenance in mind, allowing for easier access to the internal components for cleaning and repair. This reduces downtime and maintenance costs, which is particularly important in industrial settings.

Why Choose OIL GEAR PUMP ?

Selecting an oil gear pump for specific applications can offer several advantages:

1. Lubrication: Oil gear pumps are specifically designed for pumping oil and lubricants. They are ideal for applications where consistent lubrication is critical, such as in machinery, automotive systems, hydraulic systems, and industrial equipment.

2. High Pressure Capability: Oil gear pumps are capable of generating high pressures, making them suitable for applications that require oil to be delivered at elevated pressures. This includes hydraulic systems, power steering systems, and certain industrial processes.

3. Precise Metering: Oil gear pumps can provide precise metering and control of oil flow rates, ensuring accurate lubrication and operation of machinery and equipment. This precision is essential for maintaining optimal performance and preventing damage due to over- or under-lubrication.

4. compact Design: Many oil gear pumps are designed to be compact, allowing them to be installed in tight spaces or integrated into machinery and equipment with limited space availability. This compact design can facilitate easier installation and reduce overall system footprint.

Why Choose SS ROTARY TWIN GEAR PUMP?

Choosing an SS (stainless steel) rotary twin gear pump can offer several benefits in fluid handling applications: 1. Corrosion Resistance: Stainless steel construction provides excellent resistance to corrosion, making SS rotary twin gear pumps ideal for handling corrosive fluids. This makes them suitable for use in industries such as chemical processing, pharmaceuticals, food and beverage, and wastewater treatment. 2. Hygienic Design: Stainless steel rotary twin gear pumps are often designed with hygienic features, such as smooth and easy-to-clean surfaces, to meet strict hygiene standards. They are commonly used in sanitary applications where cleanliness is crucial, such as in food processing, dairy, and pharmaceutical manufacturing. 3. High Temperature and Pressure Capability: Stainless steel rotary twin gear pumps can handle high temperatures and pressures, allowing them to be used in demanding applications where fluids need to be pumped at elevated temperatures or pressures.Our Mission

Hari Vallabh Roto Industries is dedicated to pioneering excellence in fluid handling solutions. With a commitment to innovation, quality, and customer satisfaction, we specialize in manufacturing high-performance rotary equipment, including rotary twin gear pumps. Our mission is to engineer reliable and efficient pumping solutions that meet the diverse needs of industries worldwide.

Any Questions?

What specific industries does Hari Vallabh Roto Industries primarily serve with its fluid handling solutions, and how does the company ensure that its products meet the unique requirements and standards of each industry?